Background:

With over 40% of a dairy processing plant’s daily electricity consumption being used for refrigeration, process cooling optimisation is no longer an option, it is a necessity.

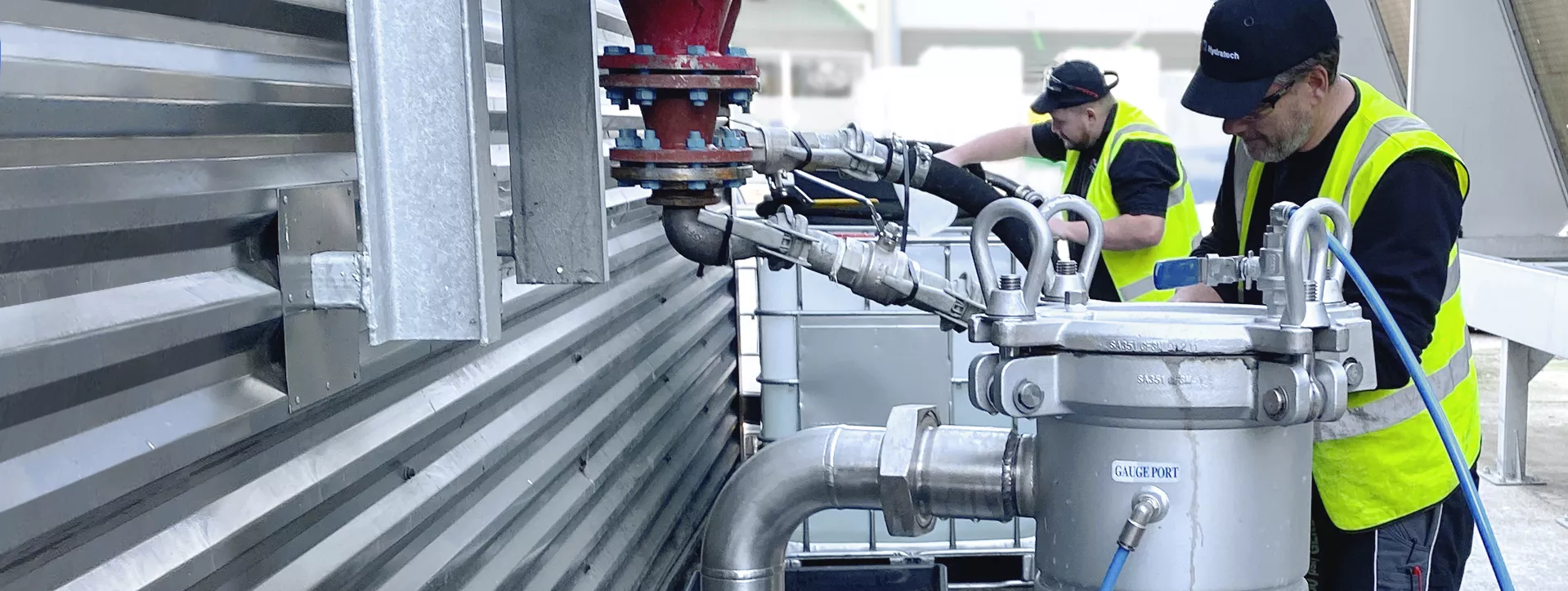

For over 25 years Hydratech have been working with the UK’s leading dairies. By establishing technical partnerships with those responsible for plant design and operation, Hydratech understand their exact application requirements, and implement a holistic approach to process cooling fluid and system management, which in turn improves system efficiency, saves energy, and reduces downtime.

Solution:

Hydratech’s fluid-centric approach to dairy process cooling optimisation encompasses:

- Fluid Selection

- Fluid Monitoring

- Fluid Management

Fluid selection:

Heat transfer fluid characteristics have a direct and long-lasting impact on chiller-based cooling system performance, production output, energy consumption and operational lifespan.

Efficient thermal energy transfer, minimal pumping-energy consumption, long-term preservation of pipework/system components, cost, and minimal environmental impact, are all key considerations when selecting an appropriate formulation, mixing ratio and compatible inhibitor package.

Utilising over 100 years combined experience in all aspects of cooling and heating applications, Hydratech's team of chemical, mechanical and sales engineers support the dairy industry with expert advice on fluid characteristics and selection.

Fluid monitoring:

Based on many years of experience, it is not uncommon for the maintenance of dairy cooling systems to be overlooked. Under such circumstances various issues can develop, including advanced corrosion, biological fouling, and sediment formation - all of which have a direct and negative impact on heat transfer efficiency, pumping performance and energy consumption.

Hydratech’s in-house laboratory carries out analytical testing of dairy coolants, primarily microbiological and chemistry testing. By taking a proactive approach to fluid analysis, those responsible for managing or maintaining cooling systems at dairy plants can detect issues early, taking remedial action before fluid efficiency and system condition are compromised.

Fluid management:

The correct maintenance of a dairy process cooling system is essential if efficiency is to be optimised and operating costs are minimised. By combining expertise in water-treatment chemistry, fluid-thermodynamics and mechanical engineering, the Hydratech Services division provides a comprehensive range of services for dairy plants – including flushing and pre-commissioning, contamination remediation, inhibitor treatment, and fabrication - to improve productivity, minimise downtime and reduce risk.

Key Takeaways:

Selecting the right heat transfer fluid requires careful consideration. Hydratech work closely with dairy process engineers and maintenance teams, to ensure the right thermal fluid is chosen and optimum performance and cost savings are achieved.

By taking a proactive approach to fluid analysis, dairy plants can detect issues early and take remedial action before fluid efficiency and system condition are compromised.

To complement their fluid range, Hydratech provide a full range of services to support dairy process cooling operations. These extend from over the phone/email consultancy, through to hands-on fluid management, incorporating flushing and conditioning of systems, pre/post commissioning, fluid fill, PPM and long-term monitoring and maintenance.