Glycol & Antifreeze Products

Hydratech’s high performance glycol and antifreeze solutions are formulated to maximise CoP via a comprehensive understanding of fluid dynamics and thermodynamics.

More about Glycol & Antifreeze ProductsSystems that have not been properly maintained are particularly at risk, as well as those that have been altered or upgraded. It can be difficult to evaluate the quality and protection qualities of the heat transfer fluid following maintenance work. Often, closed loop cooling systems are topped up with uninhibited water, resulting in a risky dilution of antifreeze and inhibitors.

Incorrect glycol concentration during the winter months can impact hugely on any cooling system, potential issues include:

System failure and repairs

If freezing water is left to expand past the diameter of condenser pipes, the internal pressure will cause them to rupture. As well as the potential repair costs, many firms are forced to close down for days or even weeks.

Flood damage

Not only can a water leak cause damage to property, stock and assets, but the interruption to the day-to-day business operations can have devastating financial consequences.

Your equipment warranty may be voided

Many chiller manufacturers will discredit their warranties if you have not maintained the correct levels of glycol in chilled systems - resulting in the warranty for your equipment being voided.

Increased energy costs, reduced output

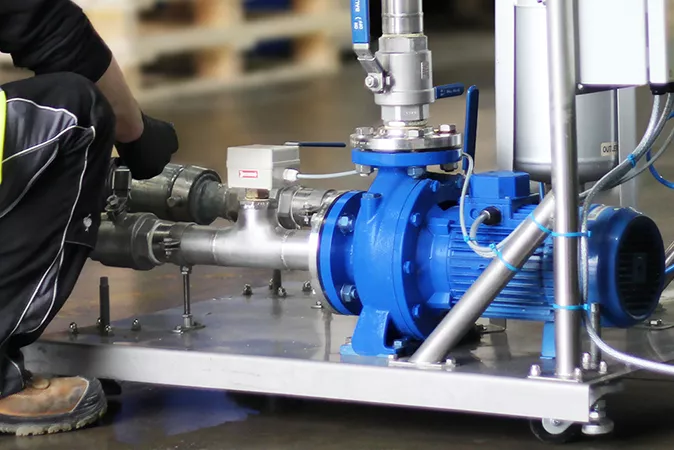

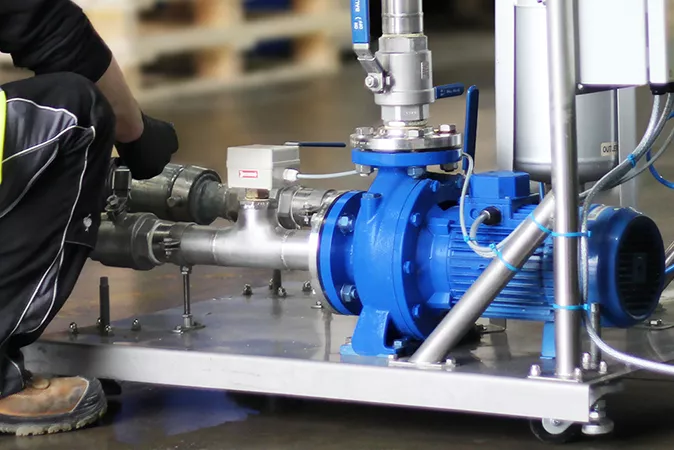

Pumps will have to work harder to push water through the pipes, as the water starts to freeze in the system. The decrease in flow velocity will reduce production and increase operational costs.

Types of Glycol

The two major types of glycol used in chilled water and closed loop systems are Ethylene Glycol and Propylene Glycol. Ethylene glycol offers the most efficient heat transfer, is significantly less viscous than PG and unit cost is usually lower. The main drawback however is its toxicity to humans and animals.

Propylene glycol was developed to replace Ethylene Glycol for use in food and beverage processing systems or where there is a requirement for a non-toxic classification. Propylene Glycol has a much lower capacity for efficient heat transfer, compared with Ethylene Glycol based mixtures - It is also much more viscous at low temperatures and thus provides more of a challenge to pump.

In 2010 Hydratech added Coolflow DTX® to their range of process cooling fluids. DTX is a high-performance non-toxic heat transfer fluid that is based on Ethylene Glycol, blended with a detoxification additive. The game changing fluid combines the thermal efficiency and low viscosity associated to Ethylene Glycol, with the non-toxic rating of Propylene Glycol. The list of DTX adopters is now extensive and includes Arla Foods, Mϋller Dairy, Waitrose, Airbus, Siemens and BrewDog.

The cost saving benefits of dosing a new or existing (retrofit) system with Coolflow DTX® are particularly favourable in the current economic climate.

For example, given the current rates a potential saving of over 30% per installation could be made if DTX replaced Propylene Glycol in a proposed 20,000 Litre system (protected to -15°C).

How much glycol will I need for my system?

Selecting the correct type and concentration of chiller glycol is very important. The glycol type should already be known and recorded in the commissioning documents or maintenance logs for your systems.

Hydratech Services can assist with glycol determination analysis if it is not known – it is especially important to verify this for food or beverage process applications.

Too much glycol or too high a % will cause system inefficiencies - through reduced heat transfer ability and pumping capacity. Not enough glycol or too low a % can lead to the expensive freeze-ups previously mentioned and can become susceptible to biological fouling.

External systems that are susceptible to freezing over winter months will need anti-freeze protection down to the lowest expected ambient temperature, with some margin advised for safety of +10%* (*Lowest temps ever recorded in UK -26.1°C - January 1982).

Taking an average between Ethylene & Propylene Glycol (considering their differing levels of freeze protection per percentage), an installed concentration of 40% v/v (glycol by volume in water) will give you frost protection down to -25°C.

High chiller glycol concentrations can impact system efficiency, with a trade off existing between anti-freeze protection and year-round performance and COP. Some therefore choose to run with glycol/antifreeze over winter months, and then plain water when the risk of ambient freezing is no longer an issue.

To prevent internal corrosion, scaling and biological fouling year-round, it is recommended that the glycol is fully inhibited and monitored every 6 months. Hydratech recommend a minimum concentration for their inhibited glycols of 25% v/v – this would provide a freeze protection average of -10°C.

For expert advice on glycol concentration levels, water quality, product selection, or fluid testing - to verify condition and frost protection, email: info@hydratech.co.uk or call 01792 586800.

Hydratech’s high performance glycol and antifreeze solutions are formulated to maximise CoP via a comprehensive understanding of fluid dynamics and thermodynamics.

More about Glycol & Antifreeze Products

Regular analysis can extend the life of both fluid and system. Hydratech’s Fluid Monitoring Program (FMP) is a very straight forward, effective way to proactively monitor closed-loop system condition.

Hydratech’s high performance glycol and antifreeze solutions are formulated to maximise CoP via a comprehensive understanding of fluid dynamics and thermodynamics.

More about Glycol & Antifreeze Products

If you need help or advice on selecting the most suitable product for your needs call one of our sales engineers today. With experience across many industry sectors we can help you find the most cost effective solution whilst meeting all your technical requirements.

Call today on 01792 586800

Sorry, we need you to complete all the required fields before we can process your enquiry.

Regular analysis can extend the life of both fluid and system. Hydratech’s Fluid Monitoring Program (FMP) is a very straight forward, effective way to proactively monitor closed-loop system condition.